The areas of eDrive and electrics / electronics show a whole range of services and capabilities with which iinovis takes a leading role in mobility.

Both areas complement each other through their natural synergies.

The eDrive & Battery Engineering division has its strengths in the planning and implementation of high-voltage projects. We have combined both areas of expertise, electric drive control and battery development, in order to offer our customers and development partners the necessary, comprehensive know-how for the development of 48V and high-voltage drive systems.

The area of Fuel Cell Systems has a promising future for iinovis, with many active projects and several years of experience our specialist are able to provide important expertise and knowledge. This enables us to embrace and accelerate future topics in the area of fuel cells.

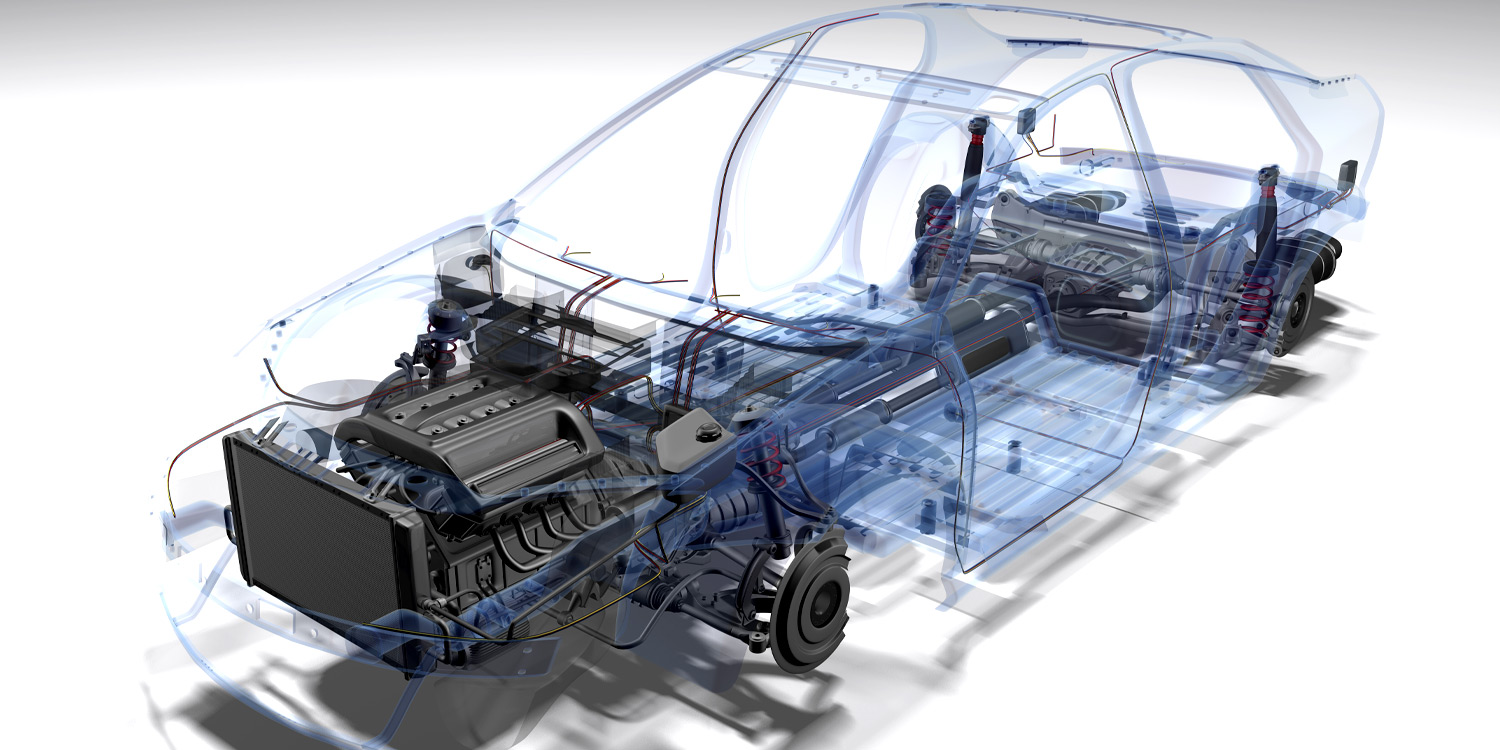

Our very intense experience in concept, prototype and series wiring harness development in the entire range (from low-voltage to high-voltage) is greatly valued by our customers. Costumers benefit from our in-house cable harness production which allows a high degree of flexibility and enables fantastic synergy effects, especially in the area of costs, as well as reaction time with the excellent quality standards.

Our innovative approach focuses on the requirements of electrical architecture development, taking into account networking and development methodology. This enables us to offer an EE architecture that also includes and fulfils the functionality, efficiency and type approval-relevant topics of functional safety and cyber security and autonomous driving functions.

Our extensive know-how in validation and verification testing provides a full-service package for our customers.

Our expertise

eDrive Integration

- Project- Process and Requirements Management

- Concept, Design and Simulation

- eDrive-Integration

- Thermal Management Design

- Performance Optimization

- System Layout

- 3D Concept Design

- Prototype and „Mule“ Design and Build

- Configuration of all components of eDrive System

Highvoltage and 48V – Battery Development

- Project-, Process and Requirements Management

- Concept, Design and Simulation

- Battery – Integration

- Thermal Managment Design

- Functional Safety (e.g. Thermal Runaway)

- Performance Optimization

- Battery Management and Charging Management Optimization

- 3D Concept Development

- Prototype and „Mule“ Design and Build

- Configuration of all components of the Battery System

Hydrogen Technology for Fuel Cells and Combustion Engines

- Concept and Series Application

- Development of Anode and Kathode Sub-Systems

- Development of the Thermal System

- Development, Application and Systemintegration of High-Efficient Humidifier for Fuel Cells

- Electrical and mechanical Integration: Housing, Crash-Design

- Algorithm Development

- Cooperation with leading German Universities (e.g. Master Study)

High- and Low Voltage Wiring Harness Development

- Wiring system development – Electrology

- Wiring

- System and cable circuit diagrams

- Wiring system development – Topology

- 3D models

- 2D production drawings

- Package Studies (incl. DMU)

- Wiring harness component development

- Change management

- Cross-section calculations

- Concept, prototype and series development

Electrical Architecture and Control Unit Development

- Development of intelligent functions at Multimedia, Communication, Lightcontrol, Body- and Security Electronics

- Project Management, Supplier Management

- Functional Safety

- Cyber-Security

- Systemdefinition and Requirements Management

- Network and Logic Design; Vehicle Integration

- Control Unit and Software Configuration / Application

- MiL, SiL und HiL – Verification und Validation

Thermal Management

- Development of Thermal Systems, Clima Controls, Standing Heater, High-Voltage Battery, Fuel Cell, Combustion Engine – Thermal Management

- Project Management und Concept Development

- System Layout und Design

- Package Studies (Digital Mock-up, DMU) and Integration

- 1D & 3 D Simulation

- Supplier Selection as support of OEM

- Supplier Management

Wiring harness production and testing

- Manufacture of cable harnesses

- Prototype and small series production (IATF 16949:2016 certified)

- Modification of complete wiring systems

- End-of-line testing

E/E prototype vehicles

- Vehicle setup: New & modified

- Integration of test equipment including set-up

- Test service

- Data recording and evaluation

eDrive &

Electrics / Electronics

Simulation

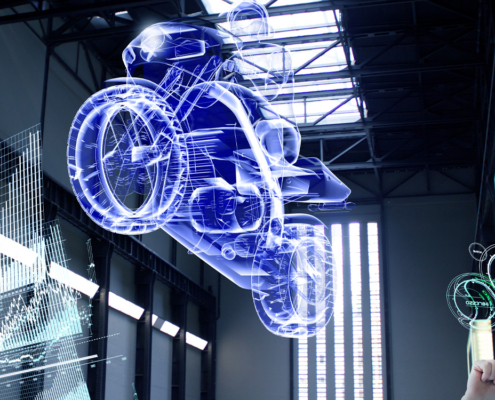

The Simulation business unit offers a wide range of services for all types of customers – from OEMs to tier suppliers. Over the years, we have developed excellent simulation expertise, ranging from complete vehicle systems to various components.

We always keep pace with technological developments and our goal is to offer state-of-the-art simulation as a service. We are specialists in the field of battery and fuel cell development.

Thermal simulation for the design of high-voltage storage systems and electronic components, as well as safety-relevant simulations, e.g. electrochemical simulations, heat propagation and venting, are among our core competencies. In addition, we have a great deal of expertise in the area of integrating high-voltage storage systems/components into the vehicle, taking into account all country-specific legal requirements, e.g. ECE R100, GB/T China.

Our expertise

Method development

- Development of simulation processes

- Automation of simulation processes

- OpenFOAM process tools and solvers

- Python, C, C++, Java, JS, VBA, Bash/Csh, Perl

System simulation

- Electrothermal simulation for HV components

- Air conditioning

- Engine cooling

Flow simulation (CFD)

- Thermal dispersion

- Aerodynamics

- Electrochemical simulation

- Air conditioning

- Electrothermal simulation

Passive safety

- Complete vehicle design

- Concept development

- Interior development

- Seat systems

- Airbag integration

Statics & Dynamics & Acoustics

- Stiffness and strength analysis

- Modal analysis

- Calculation of transient and frequency responses

- Optimisation and validation

Our Testing division offers a wide range of services, from test management to specific checks of components such as airbags, interior/exterior and chassis.

These services are offered in Germany at our Bad Friedrichshall and Wolfsburg locations.

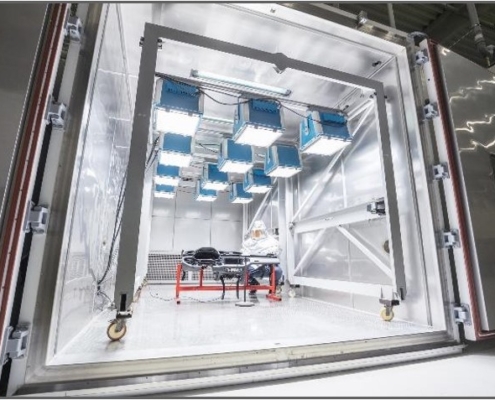

At our development center in Bad Friedrichshall we have developed and established an innovative test bench for fuel cell humidifiers. It is ideally suited for systems measuring under extrem conditions.

In addition, we carry out driving tests in different climatic zones and on different test tracks at our location in Spain and throughout Europe with 30 dedicated colleagues and more than 15 years of experience.

In addition to brake and complete vehicle testing, our portfolio offers services including logistics, project management and technical expertise. Thanks to our experts, tests can be conducted 24/7 – whether on- or off-road.

Our expertise

Safety

- Airbag-Tests

- Development, release and series monitoring

- Crash-Tests (Coordination)

Environmental simulation

- Component testing

- Climate and sun simulation

- Optical measurement

Component test

- Strength & endurance

- Stiffness testing

- Abuse testing

Test Management

- Test coordination

- Supplier coordination

- Supplier support

Test drive (Antas/Spain)

- Passenger cars, motorcycles, commercial vehicles

- Complete vehicle and brake tests on public roads and various test sites

- Equipment with measurement technology, evaluation, analysis

- Transport and logistics

- Projectmanagement

Fuel cell test

- Component tests for humidifier

Testing

Prototyping / Small Series

Thanks to our manufacturing and engineering expertise in prototyping, we have gained a broad knowledge base from individual components, test rigs through to BiW, battery housings and complete mule cars.

Our workshop for test vehicles provides our customers with optimum support during assembly and commissioning.

Due to our longtime experience, we are a reliable supplier of bodies and complete vehicles for small and exclusive series, motorsports, light vehicles as well as special purpose vehicles. Engineering and manufacturing of jigs and tools complete our portfolio.

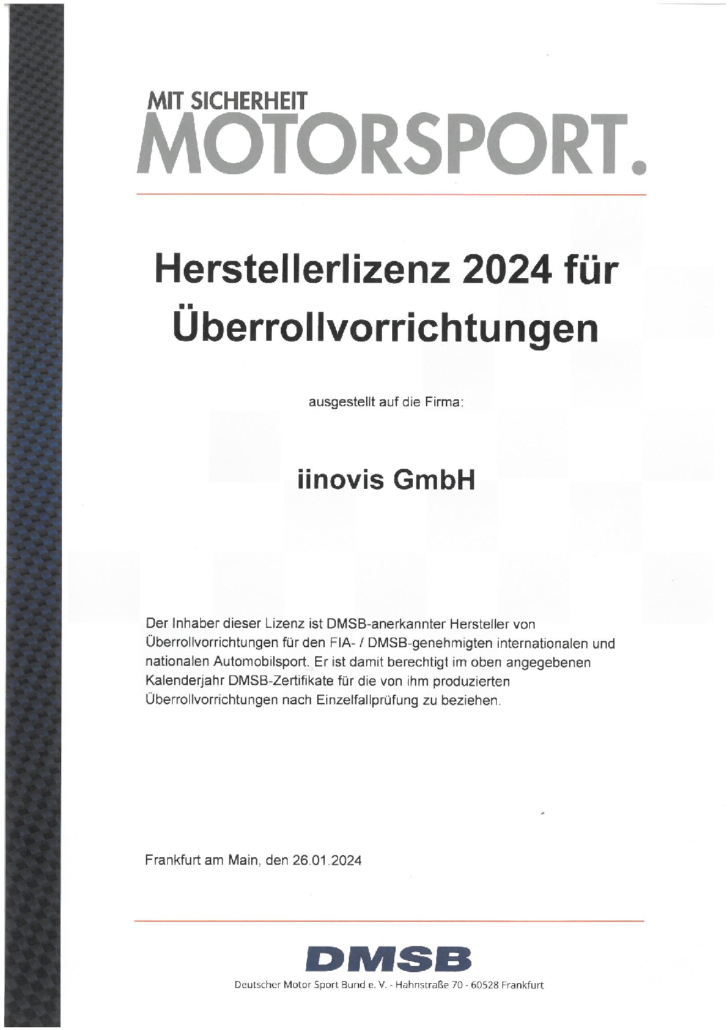

Our motorsports division provides all components and services you need, from roll cages and safety units to repairs and small series production.

Our expertise

Small Series Production

- 60m welding line with 4,000m² production area for series production of bodies

- Oven (6.5m x 2.5m x 2m) for curing and pre-curing of BiW adhesive (max. 200°C)

- Small series production vehicles

- Special purpose vehicles

- Individual & customised vehicles / vehicle Extensions

- Coachbuild

- Individual doors and hatches

- Light vehicles (L5/L6/L7) and People Mover

- Roll cages for series production sports cars

Prototyping & Test vehicles

- Mule cars and test vehicles

- Assembly of prototype engines

- Modification and adaptation of vehicles

- Show and concept cars / ergonomic concept vehicles

- BiW and rigs for sled testing

- Components and systems including milled chassis and powertrain components or battery housing structures

- Rollover protection (cages and support frames) for vehicle dynamics testing

- Test rigs for component testing

- Test drives and functional tests

Complete vehicle commissioning

- Creation of construction status documentation

- Flashing, coding and parameterization of control units

- Calibration of driving assistance systems

- Commissioning of measurement technology

- Commissioning of prototype vehicles

- Functional tests

Jigs & Tools

- Development

- Production of jigs & tools

- Calibration & initial commissioning

- Tools for body shop, armouring

- CFRP/GFRP laminates & vacuum moulding

Motorsport

- Assembly of complete racing vehicles

- Car bodies for racing vehicles, test vehicles and prototypes

- Production of roll cages (bolted and welded)

- Repair of race car bodies

- Fire extinguisher and other motorsport components

- DMSB certified